Supply chain management is the process of delivering a product to the consumer, that includes transformation from raw material to the final product. It includes demand planning, procurement planning, product planning, supply planning, sales and operations planning, and supply management.

Core Components of supply chain management:-

- Planning

- Information

- Sourcing

- Inventory

- Production

- Location

- Transportation

- Delivering

- Return of Goods

- Enabling

Planning—Enterprises need to plan and manage all resources required to meet customer demand for their product or service.

Information— Information is crucial to supply chain performance because it provides the foundation on which supply chain processes execute transactions and managers make decisions. Without information, a manager cannot know what customers want, how much inventory is in stock, and when more products should be produced or shipped.

Sourcing—Companies must choose suppliers to provide the goods and services needed to create their product.

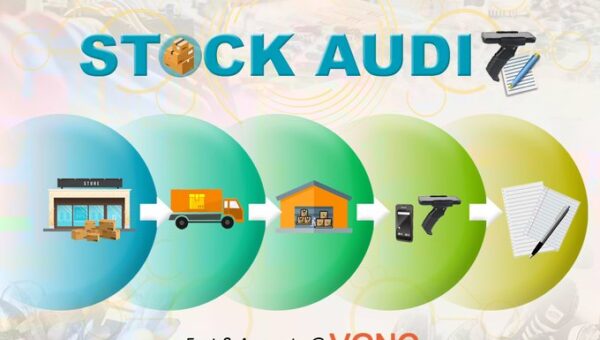

Inventory —as a component of supply chain management, It supervises the flow of goods from manufacturers to warehouses and from these facilities to point of sale.

Production—Supply chain managers coordinate the activities required to accept raw materials, manufacture the product, test for quality, package for shipping, and schedule for delivery.

Location—Facility location decisions play a crucial role in the logistics activities involved in supply chain management. In real-life settings, the optimization of location and allocation decisions is often preceded by an evaluation of the existing distribution network system.

Transportation —Transportation is a key logistics function of supply chains which runs from suppliers to customers or stores. A transportation strategy, to be effective in supply chain management, is fitting the movement of goods to the corporate supply chain.

Delivering—Often called logistics, this involves coordinating customer orders, scheduling delivery, dispatching loads, invoicing customers, and receiving payments. It relies on a fleet of vehicles to ship product to customers

Return of Goods—The supplier needs a responsive and flexible network to take back defective, excess, or unwanted products. If the produce is defective it needs to be reworked or scrapped. If the product is simply unwanted or excess it needs to be returned to the warehouse.

Enabling—To operate efficiently, the supply chain requires a number of support processes to monitor information throughout the supply chain and assure compliance with all regulations.

Why is supply chain management important?

Over the last few years, supply chains of manufacturers and retailers have become ever more tightly linked. In most of industries, retail sales trigger replenishment orders to manufacturers. Manufacturers with a well-tuned, just-in-time supply chain can automatically restock retail shelves as products are sold.

What is the impact of globalization on the supply chain?

Twenty-five years ago, one of the main reasons companies created global supply chains was to take advantage of lower wages in other countries. In general, it was fairly easy to off-set the increased shipping costs resulting from remote manufacturing.

What are the importance of Audit in Supply chain ?

Auditors who are well versed with the supply chain mechanism and understands the needs of the business can work well with the organization.

Different Audits can be performed in the supply chain are: